Introduction to Fluid

The Fluid robotic system represents a groundbreaking advancement in the realm of materials science. This innovative robot, designed to be fully 3D-printable, aims to democratize access to sophisticated robotic technology, making it available for researchers, educators, and hobbyists alike. The significance of this development cannot be overstated, as it opens new avenues for experimentation and innovation in the study of materials and their properties.

Traditionally, robotic systems in laboratories have been expensive and complex, often limiting their use to well-funded institutions and large-scale research projects. Fluid disrupts this paradigm by providing a cost-effective option priced at approximately $500, which is a fraction of the cost of conventional robotic systems. With its affordability, Fluid is well-positioned to catalyze a shift in materials research, enabling a wider array of individuals and organizations to engage with cutting-edge technology.

The operational design of Fluid prioritizes accessibility without sacrificing functionality. The inclusion of open-source components allows users to modify and enhance the robot according to their specific research needs. This encourages collaboration and knowledge sharing among users, further fostering a community built around exploration and discovery in the field of materials science.

Moreover, the ability to 3D print the robot means that users can build their systems from readily available materials, reducing the barriers to entry significantly. This feature not only promotes sustainability by minimizing waste but also empowers users to experiment with various designs and customize their robots to suit diverse applications.

Overall, the introduction of Fluid marks a pivotal moment in materials science, providing an innovative, accessible tool that could transform research methodologies and expand the possibilities for scientific inquiry in this dynamic field.

The Origin of Fluid: Key Breakthrough at Hokkaido University

In 2025, Hokkaido University experienced a groundbreaking development in materials science that paved the way for the creation of Fluid, an innovative open-source robotic system. The primary motivation behind this endeavor was the pressing need for accessible and cost-effective solutions in materials synthesis. Researchers identified that traditional methods often required significant investment and expertise, limiting their application in real-time research and educational settings.

The research team, comprised of a diverse group of scientists, engineers, and students, set out with the objective to democratize materials science. Their goal was to design a robot that could facilitate experimental processes without the constraints imposed by high costs and complex operation. This collaborative effort fostered an environment focused on innovation, ensuring that each member contributed their specialized knowledge towards creating a cohesive system capable of automating key aspects of materials synthesis.

Technological advancements played a crucial role in the development of Fluid. The adoption of open-source principles allowed the team to leverage existing software and hardware solutions, resulting in a versatile robotic platform that can easily be assembled and modified. By utilizing affordable components, Fluid was engineered to be significantly less expensive than its predecessors, thus broadening its potential for use in various institutions, particularly those with limited funding.

Furthermore, the Fluid robot is endowed with user-friendly interfaces, enabling researchers from various backgrounds to engage with the technology. This ease of use is a testament to the team’s commitment to promoting collaboration and exploration across disciplines. As the project evolved, it became evident that Fluid could revolutionize how materials are synthesized, making advanced research and experimentation more accessible than ever before.

The Technology Behind Fluid: A Fully 3D-Printable System

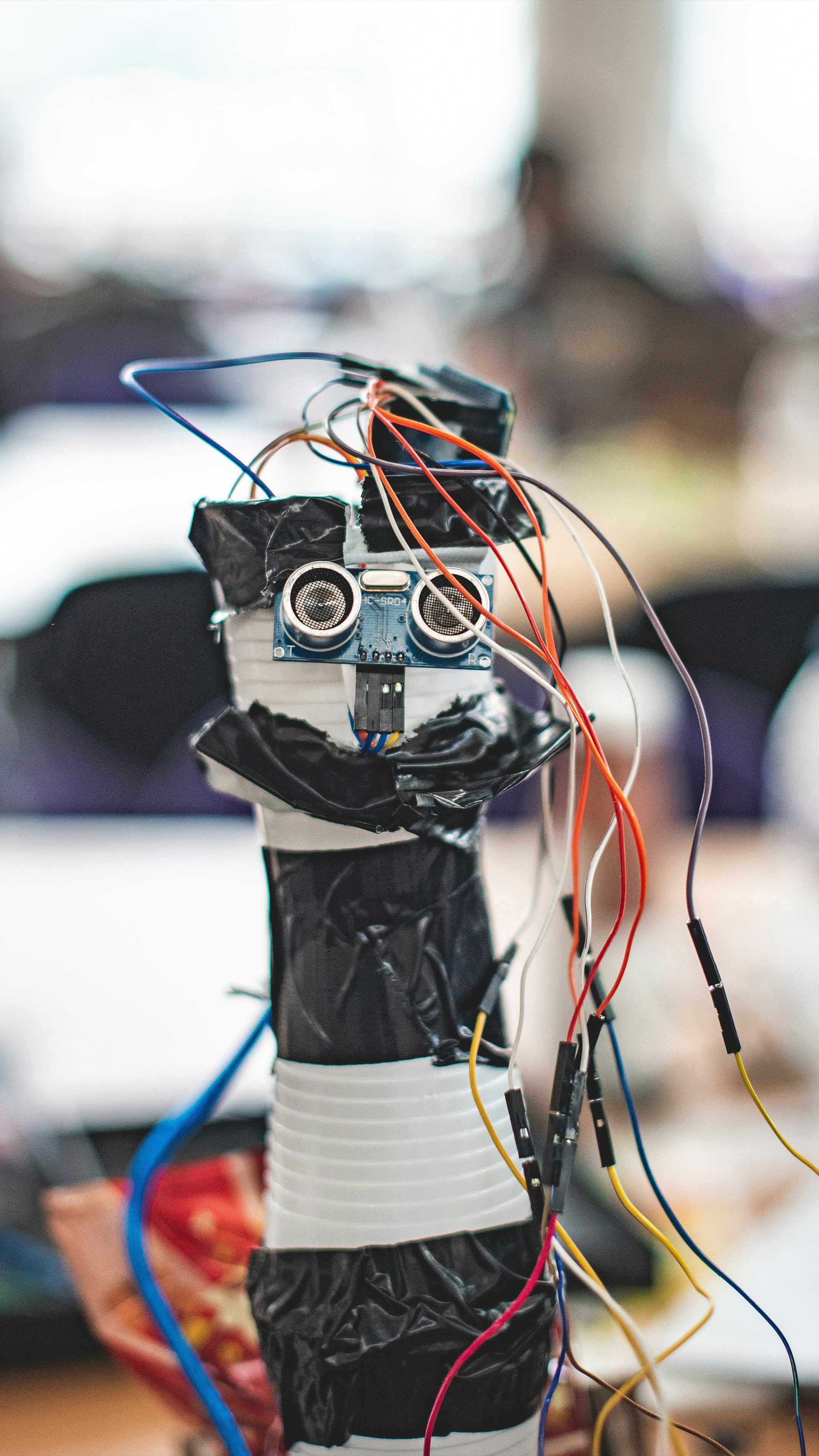

Fluid represents a significant advancement in the intersection of robotics and materials science, fundamentally redefining how affordable and accessible robotic systems can be. At its core, Fluid is a fully 3D-printable robot designed to facilitate complex materials experiments without the prohibitive costs typically associated with high-end laboratory equipment. This innovative system is constructed using a diverse array of 3D-printable materials such as thermoplastics, ensuring ease of reproducibility and customization.

The design architecture of Fluid incorporates modular components, allowing for scalability and adaptability in various experimental settings. Each part, from the base frame to the robotic limbs, is engineered for optimal performance while minimizing waste and cost. The implementation of 3D printing technology not only reduces the financial burden on researchers but also democratizes access to advanced robotics for educational institutions, startups, and individuals passionate about materials science. This aspect is critical, as it invites a broader range of contributors to explore scientific inquiries that were previously hampered by financial or technical limitations.

One of the notable engineering challenges faced during the development of Fluid was achieving the necessary precision and reliability in robotic functions, particularly during dynamic operations. Engineers utilized simulation software to assess the stress and performance of each component, ensuring that the system could withstand various operational conditions. Additionally, the integration of open-source software allows users to customize the robot’s programming to meet their specific research needs, enhancing its functionality even further.

The implications of the Fluid robot are profound; not only does it provide a cost-effective solution for conducting experiments, but it also cultivates an environment of collaborative innovation in materials science, paving the way for unique discoveries in the field. As technology continues to evolve, the potential for 3D-printable systems like Fluid to transform research methodologies becomes increasingly evident.

Cost Analysis: Bringing Robotics to the Masses

The emergence of Fluid, an open-source robotics platform for materials science, has significantly altered the financial landscape for researchers and educators. With a price point of just $500, Fluid stands in stark contrast to traditional laboratory equipment and robotic tools, which can often exceed thousands of dollars. This cost-effective approach enables a wider demographic, including educators and hobbyists, to access sophisticated tools that were previously limited to well-funded laboratories.

To illustrate this paradigm shift, consider conventional lab robots or automated synthesis systems, which can range from $10,000 to more than $100,000. These systems typically require expensive maintenance, proprietary components, and specialized training to operate. Furthermore, the software is often closed-source, marking a barrier to customization and adaptation. Fluid’s open-source nature allows users not only to modify and improve upon the design but also to share insights and innovations across a global community. This collaborative exchange enhances the overall development and utility of the platform, driving further cost reductions in materials science research.

Fluid employs affordable components readily available in electronic marketplaces, which lowers production costs significantly. Its design is optimized for maximum functionality while minimizing material expenditure, contributing to its overall accessibility. By democratizing access to advanced materials synthesis technologies, Fluid empowers a new generation of researchers, educators, and enthusiasts to explore complex scientific challenges without the financial burdens traditionally associated with high-end laboratory tools. This opens the door for innovative research projects, capable of yielding substantial contributions to the field.

Ultimately, Fluid exemplifies how cost transparency and open-source principles can facilitate a revolution in materials science, allowing users to harness cutting-edge robotic technologies while keeping financial commitments manageable. By lowering these barriers, Fluid plays a vital role in transforming how materials science is conducted across various sectors.

Applications of Fluid in Materials Science

Fluid, the $500 open-source robot, is poised to make significant contributions to various domains of materials science. Its design caters to a wide array of applications, enabling researchers to streamline their processes in basic research as well as industrial settings. One of the most compelling use cases lies in the discovery of novel materials, where Fluid can conduct automated experiments that allow for rapid analysis and optimization. This capability helps facilitate advancements in developing new composites, alloys, and other materials with enhanced properties, such as improved strength, durability, or thermal resistance.

In industrial applications, Fluid’s automated capabilities can enhance production efficiency by optimizing the material testing process. For instance, it can systematically assess multiple material samples, simultaneously evaluating their mechanical and chemical properties under defined conditions. This rapid evaluation is essential for industries reliant on durable materials, such as aerospace or automotive sectors, where performance is paramount, and lengthy testing phases can lead to delays and increased costs.

Moreover, Fluid can support research initiatives focused on sustainable materials. With the growing emphasis on eco-friendly alternatives, researchers can utilize this robot to develop and test biodegradable plastics or other green materials. The ability to rapidly prototype and analyze material properties can significantly accelerate the path toward sustainable solutions, aligning with global initiatives for environmental conservation.

In addition to these fields, Fluid’s capabilities can extend to academic research, enabling students and emerging scientists to engage in hands-on experiments that foster learning and innovation. By democratizing access to advanced experimental setups, Fluid encourages a collaborative approach to material discovery, ensuring that diverse voices and innovative ideas contribute to future breakthroughs in materials science.

Impact on Education and Research Communities

The introduction of Fluid, an open-source robotic system priced at just $500, stands to significantly influence both educational institutions and research communities. Its low-cost nature democratizes access to advanced robotics and automation, making it an invaluable tool for educators and researchers alike. By allowing learning institutions to integrate such technology into their curricula, students gain hands-on experience with robotics, programming, and materials science, key fields that are increasingly relevant in today’s technological landscape.

Furthermore, Fluid’s open-source framework fosters an environment of collaboration and innovation. Educators can adapt the robot for various educational levels, tailoring it to suit the needs of both novice and advanced students. This flexibility encourages interdisciplinary projects that can merge principles from physics, engineering, and biology, thereby enhancing critical thinking and problem-solving skills. Students are no longer limited to theoretical studies; they can engage with real-world applications, working directly with the robot to understand complex concepts. This practical experience can significantly enrich their learning process.

In the realm of research, Fluid enables academic and industrial research teams to pursue experimental work without the prohibitive costs often associated with robotic systems. The accessibility of Fluid promotes collaborative research initiatives between universities, facilitating joint projects that can lead to breakthroughs in materials science and other fields. Institutions that may have previously lacked the resources now have the opportunity to participate in cutting-edge research, leading to a more equitable distribution of knowledge and technological advancement. With the ability to customize and share modifications openly, researchers can build upon each other’s work, accelerating discovery and innovation across the global scientific community.

User Experience: Building and Operating Fluid

The experience of assembling and operating Fluid, the innovative open-source robot, is designed to be as user-friendly as possible, catering to researchers and hobbyists alike. Accessibility plays a significant role in this process, as the design files are readily available online, allowing users to download and modify them to fit their specific needs. The open-source nature encourages collaboration and sharing of best practices, paving the way for a supportive community dedicated to enhancing the user experience.

Printing the components of Fluid is straightforward, as they are optimized for a range of 3D printers. Users have reported that the design files are compatible with various materials, enabling customization based on individual project requirements. The assembly process is complemented by comprehensive step-by-step guides, which facilitate ease of construction. Furthermore, the modular design allows users to replace or upgrade specific components without needing to overhauling the entire system. This flexibility is particularly useful as users’ needs evolve over time.

The user interface for controlling Fluid is another highlight of the experience. It features a clean, intuitive layout that simplifies navigation, even for those who may not be technologically inclined. Early users have emphasized the importance of a responsive interface, which allows for seamless adjustments to experimental parameters in real-time. Feedback from the community indicates that the user experience has been enhanced by continuous updates and improvements based on user suggestions.

Testimonials from early adopters illustrate both the practical benefits and challenges faced. Many users have praised Fluid for making advanced materials science experiments more accessible, significantly enhancing their research capabilities. However, some have noted that initial setup can be complex for those unfamiliar with robotics. Overall, the user experience with Fluid continues to evolve, driven by the open-source model and an engaged community committed to refining the technology.

Future Directions: Upgrades and Community Contributions

The Fluid robotics platform is continuously evolving, with a clear roadmap outlining several planned upgrades and enhancements aimed at bolstering its capabilities in materials science. These initiatives encompass a variety of improvements, including hardware upgrades, software enhancements, and the integration of advanced algorithms to increase the efficiency and precision of experimental procedures. One primary area of focus will be on upgrading the robot’s sensor technology, allowing for better real-time data collection and analysis. As materials science becomes increasingly reliant on complex variables, enhancing the analytical capabilities of Fluid will be crucial.

Community contributions play a pivotal role in the evolution of the Fluid platform. By fostering an open-source environment, Fluid encourages developers, researchers, and enthusiasts to contribute their insights and innovations. This not only results in an accelerated pace of advancement but also ensures the platform remains adaptable to emerging needs in the research community. Collaborations between users allow for the refinement of the design and the introduction of new features based on practical applications. As more users engage with the Fluid system, a wealth of diverse perspectives and expertise is integrated into future iterations, facilitating a robust ecosystem of innovation.

Moreover, the flexibility offered by the Fluid platform means it is well-positioned to expand its applications beyond traditional materials science. Future upgrades may aim to incorporate capabilities relevant to fields such as bioengineering or nanotechnology, potentially expanding the user base and application areas. As more institutions and individuals harness the power of Fluid, the collective efforts will serve to enhance its functionalities, ensuring it meets the ever-evolving demands of scientific research. This collaborative approach not only strengthens the Fluid community but also helps in creating meaningful advancements in the landscape of robotics and materials science.

Conclusion: The Future of Materials Science with Fluid

Fluid stands at the forefront of a transformative era in materials science, heralding a significant shift in how research and experimentation are conducted. Its open-source framework not only democratizes access to advanced robotic technology but also fosters an environment of collaboration among scientists and researchers worldwide. This democratization is crucial, as it enables a broader array of practitioners to contribute their insights and innovations, thus accelerating the pace of discovery within the field.

One of the key benefits of the Fluid robotic system lies in its affordability. At only $500, it allows institutions with limited budgets to harness cutting-edge technology that was previously only accessible to well-funded laboratories. This financial accessibility encourages experimentation and exploration of new materials which can yield groundbreaking advancements across various industries, from energy storage to drug development.

The collaborative potential of Fluid cannot be overstated. By allowing researchers to share designs and protocols easily, it cultivates a global community dedicated to advancing materials science. Such collaboration encourages interdisciplinary communication, leading to a cross-pollination of ideas that can drive innovation. Furthermore, the reusable nature of Fluid’s components supports sustainability efforts within scientific research, minimizing waste and reducing costs in material experimentation.

As Fluid continues to evolve, it symbolizes a paradigm shift toward a more open and participatory approach in scientific research. The importance of fostering an inclusive environment for experimentation cannot be overstated; it lays the groundwork for innovative breakthroughs. With Fluid as a catalyst, the future of materials science appears promising, marked by a collective effort to push boundaries and explore uncharted territories, ultimately enhancing our understanding and manipulation of materials for various applications.